Fiberox

- Home

- Fiberox

About Fiberox

Fiberox is an innovative company focused on the development and production of composite reinforcement systems. These systems are designed to replace traditional steel reinforcement in concrete, resulting in a more durable, cost-effective and environmentally friendly alternative. Fiberox’s composite bars are manufactured with advanced epoxy resins and glass fibers, providing high durability and resistance to corrosion and chemical exposure. With applications in construction, infrastructure and even military projects, Fiberox aims to transform the construction industry.

Unmatched Performance and Reliability

CORROSION-RESISTANT

ELECTRICAL INSULATOR

TREBLE

NON-MAGNETIC

A Revolution in Building Materials

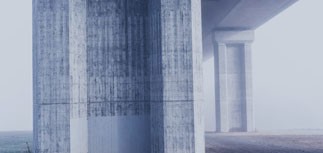

Fiberox composite bars are versatile and can be used in a wide range of construction projects. Whether in residential construction, industrial buildings or infrastructure such as roads and tunnels, these bars offer superior performance where traditional steel reinforcement falls short. Their light weight makes them easier to transport and install, while their resistance to chemicals and harsh environments ensures longevity and reduced maintenance. From hydraulic structures to electrical installations, Fiberox offers a solution that minimizes maintenance costs and maximizes efficiency

Environmental Friendliness and Sustainability

Fiberox composite rods contribute significantly to making the construction industry more sustainable. Compared to steel, Fiberox production requires much less energy, leading to a reduction in CO₂ emissions. In addition, the rods are corrosion resistant and have a long service life, resulting in less maintenance and replacement, and thus less waste of resources. When disposing of composite rods, less problematic waste is generated, and their light weight also reduces the need for heavy vehicles for transportation, further reducing harmful emissions. Fiberox fits perfectly into a strategy of circular economy and sustainable construction.

Revolutionizing Construction with Fiberox

Technical Data of Fiberox Reinforcement Systems

Tensile strength (MPa)

Thermal conductivity (W/mK)

Corrosion resistance

Innovative solutions to diverse challenges

Ready-made concrete units

Building construction

Water and marine structures

Road and rail infrastructure

Infrastructure and industry